The Allwyrm Limited Slip Differential

Written by Alan Wenbourne in May 2022

The article A Clutch of Differentials included reference to a patent by which I intended to seek provisional cover to protect my intellectual property (IP) regarding an invention for a geared torque-biasing differential.

Time passed (some of the reasons were described in The Story of My Hummer), during which several sessions aimed at writing the patent and creating drawings still did not produce a document suitable for the purpose. Despite having compiled several patent documents during my career, putting these into the correct format was aided by a patent attorney, the outcome of which were descriptions littered with so much legal jargon that I was unable to recognise them as my ideas! Not being prepared to employ an attorney for this private project meant that learning to write legal gobbledygook only added to the burden.

Laziness prevailed until in 2010, when I arranged a meeting with Quaife, the company specialising in limited slip differentials for sport and competition vehicles, with the idea of selling it to them. This required writing a confidentiality agreement to protect both our interests. Unfortunately the Invex® gear technology developed by Gleason Corp, and used in the Torsen T-1 (Type A) differential on which my invention depended, was not in the realm of Quaife’s experience or manufacture. They specialise in differentials using helical gear forms similar to the Torsen T-2 (Type B) units, so they declined to take up my invention.

As more time and lethargy passed, I came to the conclusion that new designs or versions of mechanical geared torque biasing differentials were becoming less likely to be used in automotive applications, certainly as inter-axle differentials, due to the advent of electro-hydraulic clutches, such as the Haldex type, which are more prevalent in vehicles incorporating all wheel drive (AWD) and traction control. These units are electronic speed control (ESP) using oil immersed multi-plate clutches that offer infinite inter-axle speed control through hydraulic pressure modulated slip.

I believe my invention is a patentable improvement on an existing principle, as it is well known that the Torsen T-1 differential suffers manufacturing, production, cost and assembly issues. Despite this it was used in the up-market, high-performance and off-road vehicle sectors, some of which were mentioned in the earlier article. However, since many of these applications no longer exist, and modern vehicles are equipped with more flexible systems using computer-controlled electronic clutches for traction control, I think the future of mechanical torque biasing is limited. For this reason I have decided it is time to disclose my invention to the Meccano fraternity, which would at least secure my prior art rights and lessen my guilt at not pursuing the patent application.

Timeline of the Torsen Differential Ownership Rights

- 1958: Vernon Gleasman’s patent

- 1982: Gleason Corporation buys patent

- 1994: Zexel assumes ownership

- 1999: Robert Bosch buys majority share

- 2003: Toyoda Machine Works buys Torsen

- 2005–2011: Toyoda and Koyo Seiko merge to form JTEKT Corporation

Torque Biasing Principle

The worm type helical tooth form takes advantage of the property that a worm drive is non reversible — i.e. the wheel cannot drive the worm. This is substantially true for a single start (single tooth) worm because the lead angle is less than the angle of friction. However, under load a single start worm and wheel may creep due to vibration, but this is not a very controllable condition.

The application of a multi-start worm and wheel (or helical gear) combination leads to the possibility of back-driving, albeit inefficient due to the frictional resistance when the lead angle is little more than the angle of friction.

It follows that the amount of back-driving resistance can be predicted and controlled by managing the lead angle, tooth geometry, lubrication etc.

The Torsen differential, with its small tooth number worm (or helical pinion) meshing with a wrap-around matching wheel (Invex® gearing), provides significant sliding surface areas that enhance frictional resistance to motion to a determinable level.

This frictional resistance is utilised to control the amount of spin or slip that one wheel may experience under low traction conditions or when one wheel is off the ground. The resultant residual torque within the differential is applied to the other differential output shaft to provide traction to the grounded wheel.

The actual geometry of the gearing is designed to suit specific applications such as SUV, truck, rally car, luxury car, front or rear inter-axle differential, etc.

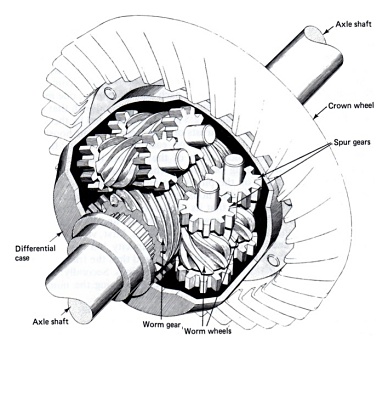

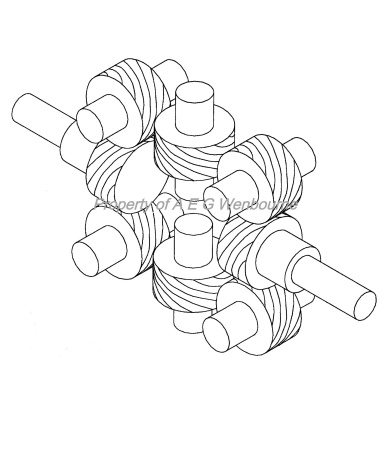

For reference, images of the Torsen differential and my Meccano model of it are reproduced in figures 1 and 2.

Figure 1 Cutaway of the Torsen T-1 differential

Figure 2 Meccano model of the Torsen T-1 differential

The Allwyrm Concept

I named my invention ‘Allwyrm’ — ‘all’ from the fact that the device uses a full complement of worm type helical gears and ‘wyrm’ being Old English for worm.

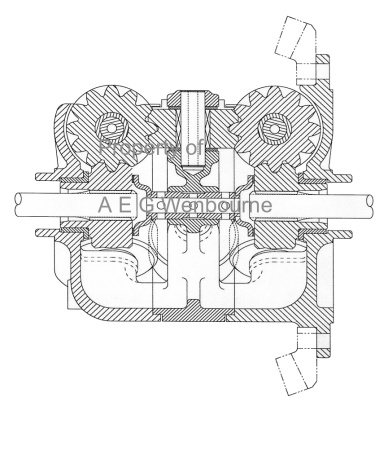

The principle is shown in the schematic, figure 3, and as a practical design in figure 4. These drawings were prepared for the potential patent application.

Figure 3 A two path schematic of the Allwyrm

Figure 4 A practical design for manufacture

My claims to improvements over the existing design are:

- Elimination of the complex compound spur/helical satellite gears and the associated problems of maintaining true index relationship between each toothed element due to natural machining and fabrication tolerances.

- Less demand on the accuracy requirements of the journals locating the satellite gears in the housing.

- More helicoidal form gears, providing greater torque biasing for traction control.

- The gears could be designed as common components.

- Utilizes fewer gears.

- Does not require gears to be index aligned during manufacture or assembly.

- Facilitates a smaller diameter assembly.

- Enhances the principle of torque biasing.

- Easier and less expensive to offer different levels of torque bias.

- Simpler construction.

- Increased durability through more effective tooth load sharing.

- Reduced manufacturing cost.

- Reduced noise, vibration and harshness (NVH).

These claims indicate the value of this invention, in that it could be engineered and manufactured using current knowledge and technology. Also, very little development time or cost would be required in bringing the design to market.

The Torsen T-1 (Type A) differential is used only in the high-end market due to its manufacturing cost. This invention could take the geared torque biasing differential into the volume automotive market.

Allwyrm Differential Meccano Models

Inspiration for the new design came about whilst modelling the Torsen version and the thought that there must be a way of achieving the same effect without using the ‘ganged’ or compound spur and helical satellite gears, which are the bane of the manufacturing process in the real thing. Eliminating the spur elements and adding a crossed helical gear between them was the result. This would add some length to the unit but reduce the overall diameter, the later always being desirable in vehicle design for reasons of ground clearance. Hence the fairly simple gear train of figure 3, which could be easily translated into three or four path arrangements also.

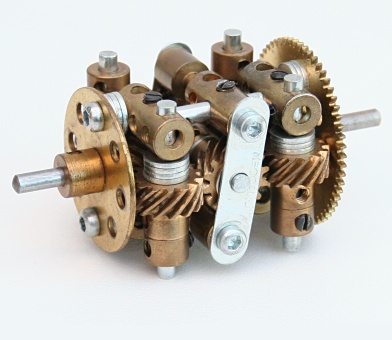

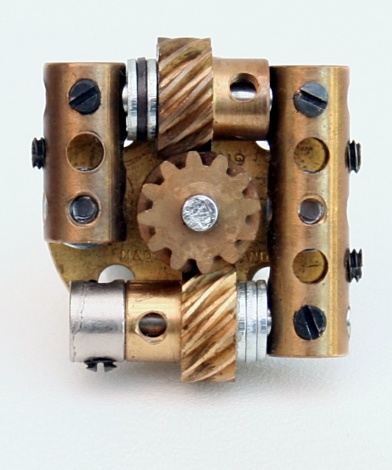

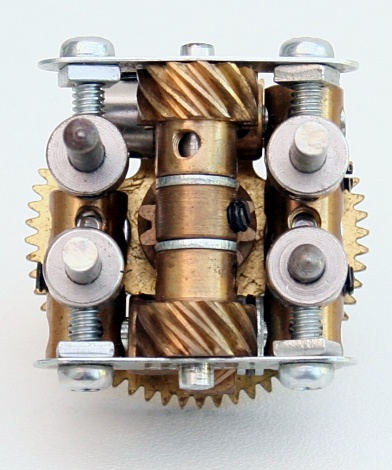

The idea of modelling it in two versions developed, one based on Meccano 14-tooth helical pinions, the other based on Exacto 12-tooth helical pinions.

Both models are of a two path arrangement — i.e. there are two mesh paths between each half shaft. Three or four path versions have not been considered at this stage.

In the Exacto version the pinions are left-hand helices, probably because I had more of them initially. With crossed helicals they have to be the same direction of helix but can be either hand. The only saving in space that the Exacto version offers is 1/8” (3mm) less in length.

Although the models use 45° helix angle pinions, the frictional resistance is apparent when one side is relieved of constraint.

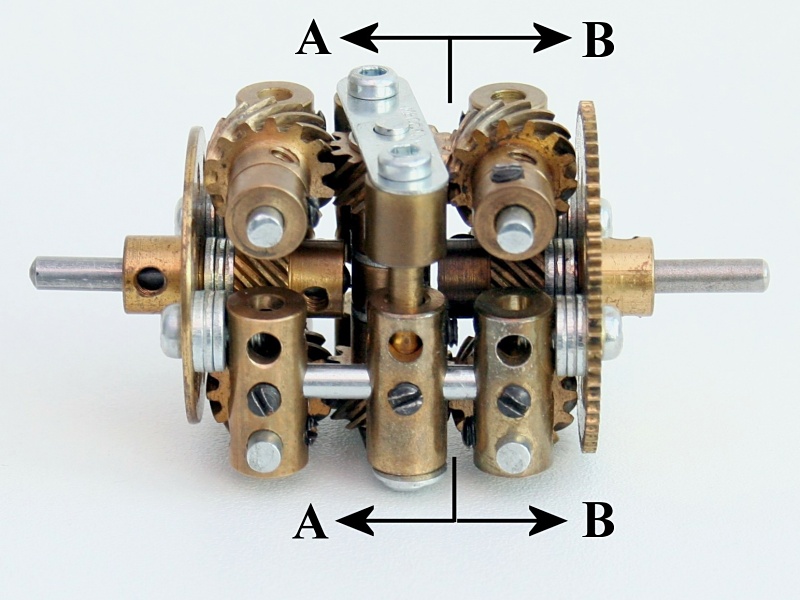

Figure 5 The Allwyrm differential using 14-tooth Meccano helical pinions

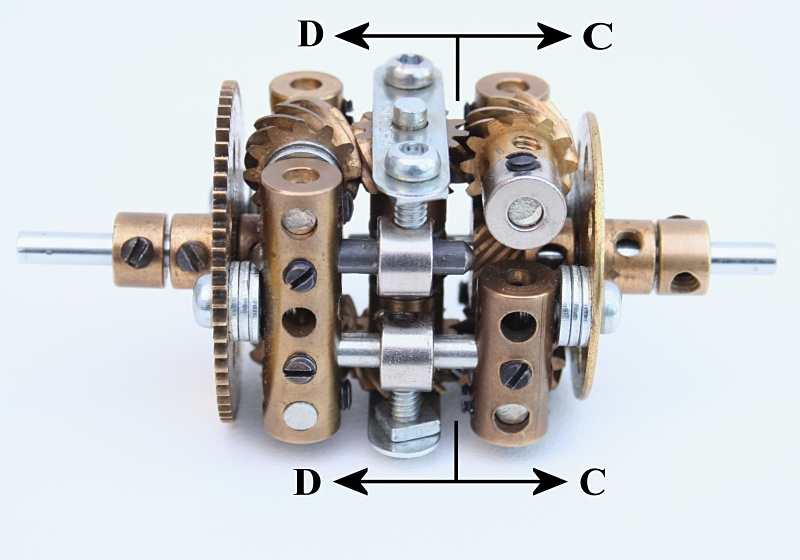

Figure 6 The Allwyrm differential using 12-tooth Exacto helical pinions

The following figures show how each version is constructed by orthographic projection of sectional views from each assembly.

Figure 7 Side elevation of 14-tooth helical geared Allwyrm differential

Figure 8 Sectional view on arrows A-A of 14-tooth Alwyrm differential

Figure 9 Sectional view on arrows B-B of 14-tooth Alwyrm differential

Figure 10 Side elevation of 12-tooth helical geared Allwyrm differential

Figure 11 Sectional view on arrows C-C of 12-tooth Alwyrm differential

Figure 12 Sectional view on arrows D-D of 12-tooth Alwyrm differential

These models are too large to accommodate a bevel or contrate gear as crown wheel without extending the length somewhat, so they are fitted with spur gears as would be normal in a front wheel drive or inter-axle layout.

I recently surveyed the US Patent Office (USPTO) files to see if anything similar to my Allwyrm differential had been patented recently, but of 262 ‘differential’-related titles, nothing came to light.

My ‘prior art’, in the form of the Meccano and Exacto models, was recorded, witnessed and dated in September 1999. If this differential design ever materialises elsewhere, remember — you saw it here first!